- Our Principals -

|

Graphicast is a world class manufacturer that specializes in the casting of ZA12 zinc alloy in graphite molds to produce net and near net shape parts. The company is built upon the foundation of delivering quality products on time and superior customer service for over twenty five years and is ISO 9001:2015 certified. Graphicast specializes in concurrent engineering, realizing that the time between design and production is often critical to a customer's success.

ZA-12 Material

Graphicast ZA-12 zinc alloy offers an excellent combination of mechanical properties, surface finish, and low cost. ZA-12's strength, hardness, and wear properties are better than any other general-purpose nonferrous casting alloy. Because ZA-12 is spark proof, it can be used in hazardous environments, including those underground.

- ZA12 vs Cast Iron: ZA12 has the same density, stronger, machines faster, better corrosion resistance

- ZA12 vs Aluminum: ZA12 is harder, stronger, better wear qualities, more stable, less warp

- ZA12 vs Bronze/Brass: ZA12 machines easily, has superior strength, hardness and wear capabilities

|

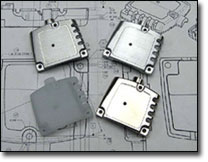

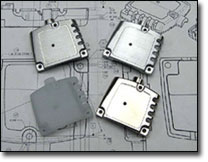

Casting Process

Using casting machines designed and built around its proprietary LTA (low turbulence automatic-fill) technology, Graphicast produces ZA-12 castings of exceptional quality and consistency. This rate- and temperature-controlled bottom-filling LTA process yields castings of increased density, lower porosity, better surface finish, and more consistent dimensions. |

Tooling

- Graphite tooling machined in house

- Secondary Machining: complete in-house High Speed CNC machining

- In-house Design & Rapid Prototype Service that delivers an as cast part machined from ZA12

|

|

The Graphicast Advantage

It is an economical alternative to sand, die and investment casting; machining; and in some cases plastic injection molding.

- Tooling is 1/10th to 1/6th that of die cast tooling and guaranteed for the life of the part

- Faster turnaround time of 4-6 weeks for a complete part

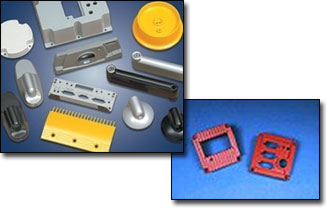

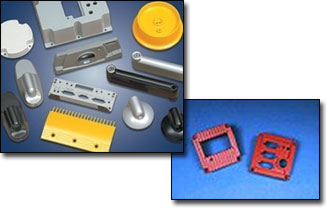

Market Specialties

Medical Diagnostic and Test Equipment

- Liquid Chromotography

- Pump Housings

|

Communication

- Front Panels

- Sensor Housings

|

Inspection Equipment

Electronic & Electrical

- Business Machines

- Measurement and Control Systems

- Circuit Breaker & Encoder Housings

- Measurement and Controls

|

Industrial Machinery and Packaging |

|

Finishes

With an attractive, naturally lustrous finish, Graphicast parts are usable straight from the mold. However, if desired, parts can be finished using the same processes and materials as those recommended for zinc die castings.

Coating options include:

- Zinc Anodized

- Colorless Chromates

- Black Chromates

- Black Electrocoating

- Zinc Plating

|

Coating options include:

- Electroless Nickel

- Chrome Plating

- Painting

- Powder Coating

|

|

Graphicast Inc.

P.O. Box 430

36 Knight Street

Jaffrey, NH 03452

Ph: 603-532-4481 -- Fax: 603-532-4261

Visit the Graphicast Inc. Website

- Request More Information - |