- Our Principals -

![]()

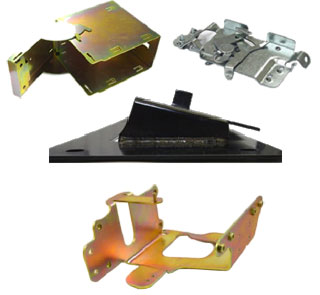

WRICO STAMPING specializes in precision custom metal stamping, assemblies, welding, deep draw stamping, progressive dies, special tooling, metal stamping dies, metal fabricating, stainless steel stamping, 3D laser cutting, metal forming, plating, Tig welding, PEM insertion, laser cutting. WRICO can also assist with your up-front design and engineering needs.

WRICO STAMPING specializes in precision custom metal stamping, assemblies, welding, deep draw stamping, progressive dies, special tooling, metal stamping dies, metal fabricating, stainless steel stamping, 3D laser cutting, metal forming, plating, Tig welding, PEM insertion, laser cutting. WRICO can also assist with your up-front design and engineering needs.

Wrico Stamping has grown to 6 buildings in 6 states with a total capacity of 340,000 square feet employing over 600 people.

Today Wrico Stamping is headquartered out of their 120,000 square foot office/manufacturing facility located in Plymouth Minnesota.

Wrico has grown to be North Americas largest short and medium run metal forming company.

ENGINEERING

Using the latest CAD/CAM software our engineering team will assist in developing the most cost effective solution for manufacturing your part.

|

|

|

SHORT-RUN STAMPINGS

Even in today's high-tech world short run metal stampings still provide a key component in the lean manufacturing model. With quick tool development and rapid set-up and turnaround times short run stamping provides an economical source of quality metal parts. Once the part design has been finalized our toolmakers fabricate the tooling necessary to manufacture the part whether that tool be a single hit, progressive, or compound die. Wrico Stamping uses the latest EDM and vertical milling methods to quickly get your parts into production.

Even in today's high-tech world short run metal stampings still provide a key component in the lean manufacturing model. With quick tool development and rapid set-up and turnaround times short run stamping provides an economical source of quality metal parts. Once the part design has been finalized our toolmakers fabricate the tooling necessary to manufacture the part whether that tool be a single hit, progressive, or compound die. Wrico Stamping uses the latest EDM and vertical milling methods to quickly get your parts into production.

- Presses from 20 to 400 tons provide the capacity to handle any size job.

- The larger presses are well suited for deep drawing, high tonnage blanking.

- Our hydraulic presses in the 200-ton range offer an even greater emphasis on speed and complexity.

MECHANICAL ASSEMBLIES & WELDMENTS

Wrico Stamping will complete small to medium sized mechanical assemblies for you. Secondary operations performed in this area would include:

Wrico Stamping will complete small to medium sized mechanical assemblies for you. Secondary operations performed in this area would include:

- Pem setting, staking, and hardware insertion

- Welding

- Resistance spot welding

- TIG welding

- MIG welding

- Robotic welding

- Finishing

- Painting, plating, powder coatings

- Packaging

Wrico works with several specialty materials such as plastics, precious metals, and perforated sheet metals.

PROTOTYPING & FLEXIBILITY

Rapid Prototypes in a variety of materials and thicknesses can be manufactured quickly using laser cutters, including 2-D and 5-axis lasers for 3-D parts. The turret and brake presses offer flexibility in production without the costs and lead time associated with special tooling.

- The flexible manufacturing system (FMS) gives us the capability for truly 'lights out' manufacturing.

- Press brakes offers tremendous flexibility in the forming of parts with standard dies.

- Turret presses are perfect for low to medium quantity production runs without the cost and lead time associated with special tooling.

- With in-house tooling Wrico offers the most efficient and cost effective manufacturing processes.

- When special tooling is required, the vertical milling centers can machine to precise tolerances.

- Short to Medium Run Stampings

- Quality, ISO 9001:2015 certified

- Economies of Scale

- Well Managed Manufacturing Burden Rates

- Experience in multiple processes, industries and materials

- Engineering support

- Technology using the best equipment

WRICO wants to be your Partner in helping to drive cost out

of your Products and Processes.

Wrico Stamping

2727 Niagara Lane North

Plymouth, MN 55447

Ph: 763-559-2288 -- Fax: 763-553-7976

Visit the Wrico Stamping Website

- Request More Information -